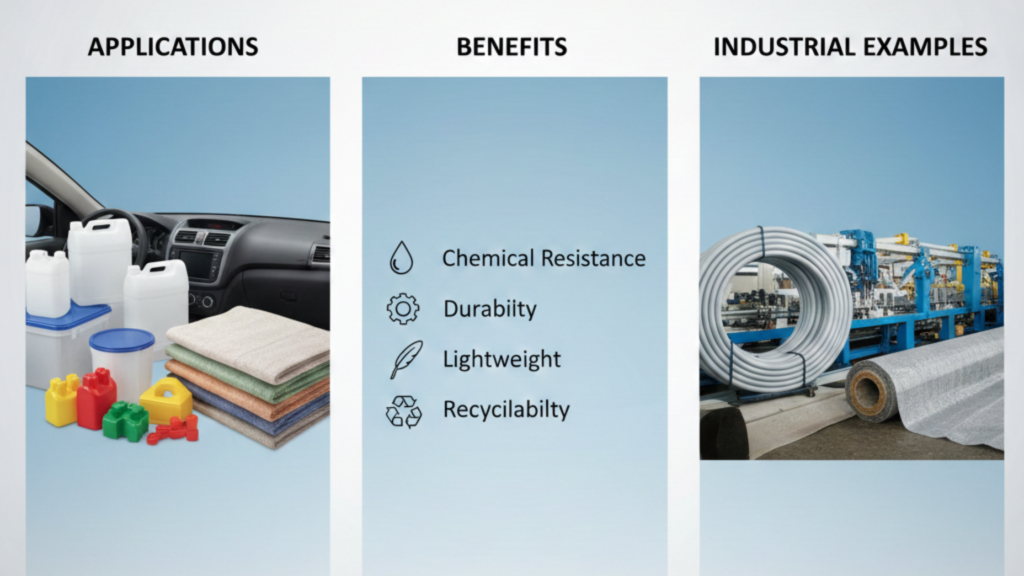

Polypropylene Uses: Applications, Benefits, and Industrial Examples

Plastic is ubiquitous, it is used in food packaging and in furniture, in medical equipment and interior car parts. However, not every plastic is identical.

Nevertheless, not any plastics are identical. Polypropylene is one of the most common and widely used plastics in the world of which many people are unaware of the products that are produced.

The problem is that improper selection of the material may affect product durability, safety, cost, and environmental performance.

This is particularly significant to the businesses which deal in production, wrapping or Industrial usage.

This guide will detail the polypropylene uses, properties, benefits, and application in real life to allow you to know why this material is so important in an industry.

What Is Polypropylene?

Definition of Polypropylene (PP)

Polypropylene (PP) is a thermoplastic polymer made from propylene monomers. It is known for being lightweight, strong, flexible, and resistant to chemicals and heat.

The consumer products and the industrial applications of polypropylene are widespread owing to these properties.

Key Properties of Polypropylene

- Lightweight yet durable

- High resistance to chemicals and moisture

- Good heat resistance

- Excellent fatigue resistance (ideal for hinges and caps)

- Recyclable (Resin Identification Code #5)

The above characteristics render polypropylene an extremely versatile material, applicable in both normal domestic products and industrial equipment.

Polypropylene Uses in Daily Life

The reason that polypropylene is so popular is that it is a substance that is used in a variety of products that we deal with on a daily basis.

Household Products

Polypropylene products used in the home comprise:

- Food storage containers

- Buckets and tubs

- Bottle caps and lids

- Kitchenware and utensils

Polypropylene is frequently used in these products due to the fact that it is food safe, durable and easy to clean.

Consumer Goods

You’ll also find polypropylene in:

- Toys

- Stationery items

- Storage boxes

- Furniture components

It can be used many times without breaking thus making it perfect to be used in consumer goods.

Industrial Uses of Polypropylene

In addition to everyday applications, polypropylene has wide-ranging industrial applications that are on the increase.

Packaging Industry

Polypropylene finds massive application in package making due to its light weight and low cost.

Common packaging applications include:

- Food containers and trays

- Flexible packaging films

- Caps and closures

- Woven polypropylene bags

It is a leading product in the packaging industry due to its moisture level and the ability to be in contact with food.

Automotive Industry

Polypropylene is also used in the automotive industry to reduce the weight of a vehicle and still retain the strength.

Uses include:

- Dashboard components

- Interior panels

- Bumpers

- Battery casings

Lightweight materials like polypropylene help improve fuel efficiency and lower emissions.

Construction Industry

Polypropylene can also find extensive application in construction because it is durable and does not react to environmental conditions.

Applications include:

- Pipes and fittings

- Insulation materials

- Plastic sheets and panels

It is very resistant to chemicals and moisture and therefore can be used in construction over a long time period.

Polypropylene Uses in Medical and Textile Industries

Medical Applications

Polypropylene is an important product in the health industry since it can be sterilized and it is non-toxic when used in the medical field.

Common medical applications include:

- Syringes

- Medical trays

- Laboratory equipment

- Disposable medical containers

It is quite safe and has excellent chemical resistance capabilities, which make it suitable in a medical facility.

Textile Applications

In the textile industry, polypropylene is used to produce:

- Carpets and rugs

- Ropes and nets

- Non-woven fabrics

- Geotextiles

Polypropylene fibers are light, strong and moisture resistant hence ideal in terms of industrial textiles.

Advantages and Benefits of Polypropylene

Why Polypropylene Is Widely Used

Polypropylene has some important benefits that encompass:

- Economical, as compared to other plastics.

- High durability and flexibility

- Chemical and moisture resistance.

- Safe for food and medical use

Such advantages are the reasons why polypropylene is chosen in so many industries.

Polypropylene vs Other Plastics

Compared to other plastics:

- Vs polyethylene: Polypropylene offers better heat resistance

- Vs PVC: Polypropylene is lighter and more environmentally friendly

This is a performance cost balance that ensures that polypropylene is a very practical material.

Is Polypropylene Safe and Recyclable?

Is Polypropylene Safe for Food Use?

Yes. Polypropylene has been considered as food contact safe and it is actively used in food containers, packaging and kitchen products.

It is not readily washed away to disarrange damaging chemicals at the usual state of use.

Is Polypropylene Recyclable?

Polypropylene is a recyclable material which has a recycling code of 5.

Although the recycling percentages are different across regions, the recyclability of it provides it with an alternative to other plastics.

Conclusion

One of the plastics currently in use is polypropylene which is very flexible. The polypropylene is used in household goods and packaging, automotive parts, medical equipment, and textiles in virtually every one of the major industries.

The reason why it is a favorite material is due to its strength, affordability, safety, and recyclability by both the manufacturers and the consumers.

Knowledge on the use and purpose of polypropylene can help you make decisions in the future whether of business or of products or even on the question of sustainability.