Ultimate Guide to FIBC Bags: Types, Uses, Benefits & Specifications

Flexible Intermediate Bulk Containers also referred to as FIBB bags are an essential solution to bulk material management in industries across the globe.

Their strong structure, large capacity and flexibility make them the preferred choice when it comes to material transportation as well as storage.

FIBC bags in the agriculture, chemical, construction, or pharmaceutical industry are safe, economical, and convenient to use in industrial practice.

What Are FIBC Bags?

FIBC Bags (complete name: Flexible Intermediate Bulk Containers) are woven polypropylene bags, large and strong, which are used to store and transport large amounts of products: grains, chemicals, sand, fertilizers, cement, plastics and others.

They can be used to work with grains and fertilizers as well as chemicals and building materials.

Primary Uses:

- Agriculture: Storage and transportation of grains, seeds and manural.

- Chemicals: How to pack powders and granules safely.

- Construction: The aggregate, cement, and sand transportation.

- Pharmaceuticals: OSHA Medicinal powder and ingredient handling.

- Mining: Saving value of minerals and ores.

What are FIBC bags used for?

They are applied in the safe storage and transportation of high tonnes of dry bulk contents in different industries.

FIBC Bags vs Other Bag Types

How FIBC Bags Differ from IBC Containers

FIBC bags do not share much in common with Intermediate Bulk Containers (IBC) except in material and construction.

The IBCs are typically hard containers composed of either plastic or metal whereas the FIBC bags are lightweight, flexible and foldable.

What is the difference between IBC and FIBC?

FIBCs are flexible and space saving whereas IBCs are more rigid in offering protection and stack easily.

FIBC vs PP Bags

Smaller single-use bags consist of polypropylene (PP) bags mostly applied to 2550 kg materials.

FIBC bags can also carry 2,000 kg and above and can even be reused hence making them a more viable option.

What is the difference between PP bags and FIBC bags?

FIBC bags are bulk reusable and larger as compared to the normal PP bags, which are used in bulk industrial purposes.

FIBC Bags Full Form and Specifications

FIBC stands for Flexible Intermediate Bulk Container.

Specifications:

Sizes & Dimensions: Vary depending on application; typical volumes range from 500–2,000 kg

Weight Handling Capabilities: Safe Working Load (SWL) of 500–2,000 kg

Materials:

- Polypropylene (PP)

- UV-resistant coatings

- Anti-static additives

- Optional colorants

What is FIBC made of?

FIBC bags are mainly composed of the woven polypropylene, which is commonly coated or treated according to a chosen industrial need.

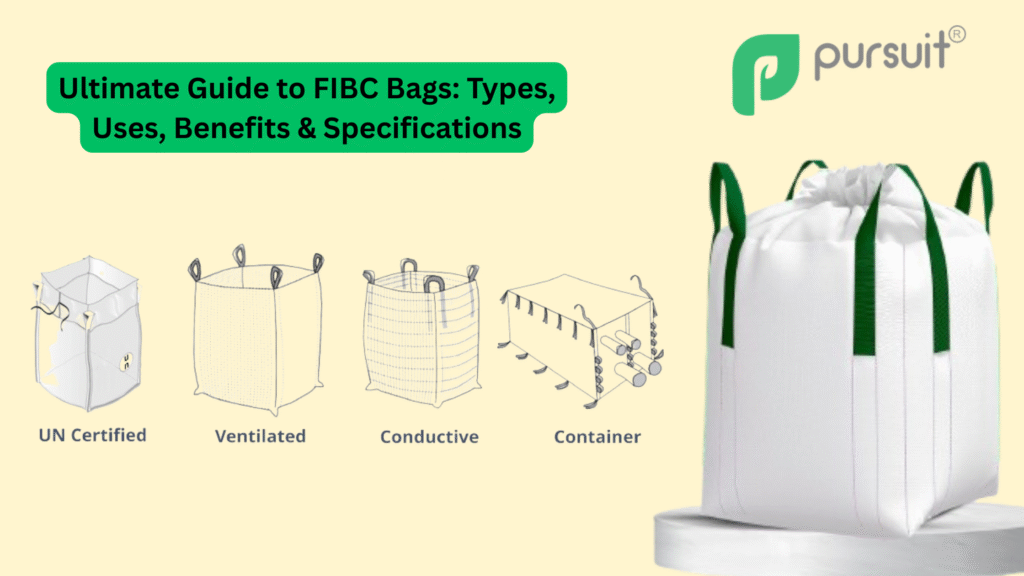

Types of FIBC Bags

By Electrostatic Classification

- Type A: Non-conductive, regular bulk bag.

- Type B: Conductive and has a little electrostatic resistance.

- Type C: Groundable conductive FIBC.

- Type D: Complete anti-static of flammable powders.

By Shape & Construction

- U-Panel FIBC: The easiest to construct, the cheapest.

- 4-Panel FIBC: stronger structure, even distribution of weight.

- Circular FIBC: Body is seamless and has high volume capacity.

- Baffle FIBC: Square in shape to make the most of the space.

- Other Constructions: Corner lift, cross corner lift, sleeve lift.

By Application / Industry

- Agriculture: Grains, seeds, fertilizers

- Animal Products: Supplements, bedding and Feeds.

- Food & Pharma: Pharma and food grade powders.

- Chemical & Hazardous Materials: Chemicals: safe storage.

- Construction & Mining: Cement, sand, minerals

FIBC Bag Styles & Tops/Bottoms

- Best Sellers: open top, duffle top, spout top, spout top with flap, conical spout top.

- Bottom Options: plain bottom, discharge spout, conical discharge spout, duffle bottom.

Such differences give the ability to customize it according to industry needs and material type.

FIBC Bag Manufacturing & Materials

Raw Materials:

- Polypropylene resins

- UV stabilizers for sunlight resistance

- Calcium carbonate

- Anti-static additives

- Colorants for product differentiation

Manufacturing Process:

- Extrusion of polypropylene into tapes

- Weaving of fabric

- Lamination or coating for additional protection

- Stitching and finishing of loops

- Quality tests to meet regulatory standards

Also Read : https://pursuitind.com/fibc-bags-manufacturer-in-india/

Choosing the Right FIBC Bag

Factors to Consider:

- Weight and material volume

- Electrostatic requirements

- Coating type (coated vs uncoated)

- Top and bottom style

Industry-Specific Recommendations:

- Agriculture: Baffle or U-panel

- Chemicals: Type D anti-static

- Construction: 4-panel or circular for heavy loads

Which type of bulk bag is right for you?

Choose based on material type, weight, and regulatory requirements.

Advantages of FIBC Bags

- Large storage capacity

- Lightweight and easy to handle

- UN certified for hazardous material transport

- Reusable and sustainable

- Customizable for prints, loops, and coatings

Common FAQs About FIBC Bags

1) What does FIBC stand for?

Ans: Flexible Intermediate Bulk Container.

2) What are FIBC bags used for?

Ans: Movement and storage of dry bulk goods.

3) What are the number of combinations of FIBC bags?

Ans: Different models according to the construction, shape, and also electrostatic classification.

4) Difference between FIBC and IBC bags?

Ans: FIBC is flexible; IBC is rigid

5) Distinction between PP bags and FIBC bags?

Ans: FIBC bags are larger in capacity, reusable and bulk.

Conclusion

FIBC bags constitute a fundamental answer to contemporary industrial storage and transportation. They are versatile, strong and adapting to a vast number of industries.

The appropriate choice of the type of the FIBC bag can guarantee safety, efficiency, and sustainability of the material handling.

In the case of companies that are in need of bulk packaging solutions of high quality, it is advisable to contact a reputable manufacturer of the FIBC bags so that you can get one that suits your exact needs.