News

Intermediate Bulk Container (IBC): Types, Uses, Design, Safety & Industry Applications

Packaging solutions in the world used in the industrial sectors are safe, efficient, and cost effective. The Intermediate Bulk Container (IBC) is one of the solutions which have revolutionized the storage and transport of bulk materials.

IBCs are known to be very durable, have high capacity and are multifunctional in the sense that they have found use in most industries including the chemicals industry, food industry, pharmaceutical industry, agriculture sector, petrochemical industry, waste water treatment and many more.

This is the ultimate guide to intermediate bulk containers with all the information about the type, design, materials used, benefits, usage, safety, cleaning, reconditioning, lifecycle, sustainability effect and other key purchasing decisions.

What Is an Intermediate Bulk Container?

An Intermediate Bulk Container (IBC) is a reusable or single-use, industrial grade container that is used in the safe storage, handling, and transportation of liquids, semi-liquids, viscous, powders, pastes, and granulated substances.

The design of IBCs allows them to be very space-saving due to their high volume capacity, and their footprint size is comparable to a pallet.

Common Features of IBCs

- Cube-shaped design

- Capacity between 500 to 3000 liters

- Stackable frame

- Pallet-compatible base

- Top filling cap and bottom discharge valve.

- Constructed of economical substances (HDPE, steel, stainless steel, composite).

Why Are They Called “Intermediate”?

They fall between:

- Small drums (200L)

- Large tank containers (20,000L+)

Hence the name intermediate bulk container.

History & Evolution of Intermediate Bulk Containers

The solution to a significant industrial problem was the invention of IBCs:

The way to carry more bulk of items without the inefficiency of small drums and the rigidity of large tanks.

Key Milestones

- 1960s-1970s: Metal IBCs on chemicals were invented.

- 1980s: HDPE plastic IBCs were introduced.

- 1990s: Composite caged IBCs gain international standard.

- 2000s: Flexible IBCs (FIBCs) transform the process of handling dry bulk.

- 2020s: IBCs with RFID sensor tracking and internet of things sensors come in.

In the current day, IBCs have become indispensable in industries in which safety, efficiency and compliance are paramount.

Types of Intermediate Bulk Containers

There are various types of IBCs based on material, structure and purpose. A breakdown is provided below.

Rigid Intermediate Bulk Containers

Rigid IBCs are tough, strong units that are composed of:

- High-density polyethylene (HDPE)

- Carbon steel

- Stainless steel

- Composite (steel + plastic)

Features

- Integrated pallet base

- Stackable frame

- Ideal for hazardous and non-hazardous materials

- Capacities: 275 gallons (1040L) & 330 gallons (1250L) are most common

Applications

- Chemicals

- Oils

- Food liquids

- Pharmaceuticals

- Petrochemicals

Rigid IBCs have the greatest durability and have a life span of years when well maintained.

Collapsible Intermediate Bulk Containers

Collapsible IBCs have the ability to creep down when not in use and this saves on return-shipping cost as well as storage space up to 75%.

Benefits

- Space-saving

- Hygienic (replaceable liners)

- Lightweight

- Ideal for food-grade and pharma products

Industries

- Cosmetics

- Pharmaceuticals

- Dairy

- Beverage manufacturing

They usually contain inner bags of plastic and an outer frame that can be reused.

Caged Intermediate Bulk Containers

Caged IBCs are the most widely used IBC type globally.

Structure

- Blow-molded HDPE inner bottle

- Galvanized steel cage exterior

- Pallet base (wood, steel, or plastic)

- Top fill port (150mm or 225mm)

- Bottom discharge valve (2-inch)

Advantages

- Affordable

- Easy to maneuver

- Ideal for liquids & chemicals

- Reusable

- Available as:

- New

- Rebottled (new bottle + used cage)

- Reconditioned (cleaned and reused both)

Such industries as agriculture, paints, chemicals, food ingredients, and detergents are controlled by such IBCs.

Flexible Intermediate Bulk Containers (FIBCs)

Also known as:

- Big bags

- Jumbo bags

- Bulk bags

- Super sacks

Features

- Made from woven polypropylene

- Designed for dry, flowable materials

- Capacity: 500 kg to 2000 kg

- Options:

- U-panel

- 4-loop

- Circular

- Baffle bags

- Conductive bags (for static-sensitive materials)

Used For

- Grains

- Sugar

- Fertilizer

- Sand

- Minerals

- Plastic granules

FIBCs are quite lightweight, cost-effective and ideal with bulk dried goods.

Materials Used to Manufacture IBCs

The choice of material lies on its chemical compatibility, stability and cost, and other factors based on the industry needs.

High-Density Polyethylene (HDPE)

Most common material for plastic IBCs.

Benefits

- Resistant to chemicals

- Lightweight but strong

- Food-grade variants available

- BPA-free

- Cost-effective

HDPE can be used in general chemicals, water, non-corrosive liquids, and beverages.

Carbon Steel IBCs

Used for:

- Oils

- Solvents

- Petrochemicals

- Industrial liquids

Advantages

- High structural strength

- Good for flammable liquids

- Long lifespan

- Easy to repair

Stainless Steel (304/316)

Applied in the industries that require purity and corrosive industries.

Benefits

- Hygienic

- Corrosion-proof

- Perfect for food and pharmaceuticals

- Withstands extreme temperatures

Used for winery, distilleries, dairy, pharmaceuticals, and acids.

Composite IBCs

Made from:

- HDPE inner tank

- Steel cage outer body

Blends the toughness of steel and the chemical resistant attribute of plastic.

Engineering Design of IBCs

IBCs follow a highly engineered design to maximize space, efficiency, and safety.

Key Design Features

- Cube shape → 25% more capacity than cylindrical drums

- Stackable frame → Multiple IBCs can be stored vertically

- Pallet base → Compatible with forklifts and pallet jacks

- Top fill port → Quick loading

- Bottom discharge valve → Easy unloading

- Four-way forklift access

- UN/DOT certification for hazardous materials

IBIS needs to be subjected to strict tests that ensure the test is durable and spill-free.

Advantages of Using Intermediate Bulk Containers

The IBCs have numerous advantages over drums, barrels, and other industrial packaging solutions.

Space Efficiency

- Cube design utilizes warehouse space better

- Stacks easily

- 1 IBC = 5 drums (approx.)

Better Transport Efficiency

- Reduced shipment cost

- Pallet-sized footprint

- Easy handling with forklifts

Enhanced Safety

- UN approved hazardous materials.

- Designed to prevent leaks, spills, and contamination

Versatility

Stores:

- Liquids

- Powders

- Semi-solids

- Pastes

- Chemicals

- Food products

Cost Savings

- Reusable units

- Lower labor cost

- Reduced packaging waste

Environmental Benefits

- Many IBCs are recyclable

- Reconditioning programs reduce waste

- Lower carbon footprint than drums

Uses and Applications of Intermediate Bulk Containers

IBCs have applications across almost every industrial sector.

Chemical Industry

Used for:

- Acids

- Solvents

- Alkalis

- Hazardous liquids

- Detergents

- Additives

The certification of safety is essential in this industry.

Food & Beverage Industry

IBCs are used to transport:

- Corn syrup

- Fruit pulp

- Oils

- Vinegar

- Chocolate

- Juices

- Dairy ingredients

Stainless steel or food-grade HDPE is preferred.

Agriculture

Used for:

- Pesticides

- Fertilizers

- Liquid nutrients

- Animal feed liquids

FIBCs are used for dry products like grains.

Pharmaceutical & Cosmetics

Used for:

- Gels

- Lotions

- Liquid chemicals

- Intermediates

- Active ingredients

Cleanliness and hygiene standards are essential.

Petrochemical Industry

Stores:

- Fuel

- Lubricants

- Solvents

- Adhesives

- Resins

Carbon steel IBCs are common.

Water Storage & Treatment

Used for:

- Rainwater harvesting

- Emergency water supply

- Wastewater treatment

- Greywater systems

Aquaponics and hydroponics tend to use clean IBCs.

Construction & Mining

Used for:

- Sand

- Cement

- Aggregates

- Admixtures

FIBCs dominate this segment.

Choosing the Right Intermediate Bulk Containe

When selecting an IBC, consider:

Type of Product

- Liquids → Rigid or caged IBC

- Dry materials → FIBC

- Hazardous → UN-certified IBC

- Food → Stainless steel or food-grade plastic

Material Compatibility

Check chemical compatibility charts to avoid reactions.

Capacity Requirements

Common sizes:

- 500L

- 800L

- 1000L

- 1250L

- 1500L

New vs Reconditioned vs Rebottled

- New → Highest hygiene

- Rebottled → New bottle + used frame

- Reconditioned → Fully cleaned and reused

Industry Certification

Look for:

- UN/DOT

- IMDG

- FDA (for food grade)

- NSF

- ISO

Safety Standards for IBCs

Safety is a critical factor in the design and use of intermediate bulk containers.

Fire Safety

Plastic IBCs can melt in fire, releasing contents.

For flammable materials, use:

- Carbon steel IBC

- Stainless steel IBC

Handling Safety

- Always use forklifts or pallet jacks

- Follow weight limits

- Secure during transport

Labeling Requirements

Hazardous goods must display:

- UN number

- Hazard class

- Compatibility details

Leakage Prevention

Regular checks for:

- Valve integrity

- Cap tightness

- Cage stability

- Cracks or punctures

Maintenance, Cleaning & Reconditioning

Reconditioning prolongs life of IBCs and wastes are minimized.

Cleaning Process

- Emptying the container

- Steam or chemical cleaning

- Pressure washing

- Drying

- Inspection

- Valve replacement

- Leak testing

Reconditioning Types

- Rebottled IBC

- New plastic bottle + used cage

- Reconditioned IBC

- Cleaned bottle + cleaned cage

- Washed IBC

- Economical but not for sensitive materials

Environmental Impact & Sustainability

IBCs support sustainable industrial practices.

Environmental Benefits

- Reduced packaging waste

- Long service life

- Lower CO₂ output than drums

- Recyclable materials

- Supports circular economy

Future of Intermediate Bulk Containers

The future of IBCs includes:

- Smart IBCs with sensors

- Digital tracking (RFID, IoT)

- Stronger, lighter materials

- Enhanced safety features

- Sustainable manufacturing

Conclusion

The contemporary bulk material handling has turned into intermediate bulk containers. They are essential in almost all sectors of industries due to their durability, efficiency, versatility and safety.

IBCs are of incomparable value and performance whether they are involved in transportation of hazardous chemicals or storing of food ingredients and even in handling of dry materials.

Their affordability, space-saving nature, and the ability to fit into most industries make IBCs have the potential to remain a fundamental part of the global supply chain decades into the future.

FIBC Full Form: Flexible Intermediate Bulk Container (Meaning, Types & Uses Explained)

The FIBC full form is Flexible Intermediate Bulk Container.

- Flexible – The bag is soft-sided and foldable

- Intermediate – It carries 500–2,000 kg (medium/bulk capacity)

- Bulk – Used to store/transport bulk materials

The FIBC is a high capacity, robust, industrial bulk bag constructed of a woven polypropylene fabric, forming a bag that is used to facilitate, store and transport dry, flowing substances such as grains, powders, granules, sand, fertilizer, chemicals and building products.

They are lightweight, strong, recyclable and have a heavy capacity of up to 2,000–3,000 kg and therefore they are one of the most preferred bulk packaging solutions in the world.

This elaborate manual covers the definition of FIBC, varieties, manufacturing, dimensions, advantages, usage, safety standards and reasons why industries rely on the use of the bags.

What is an FIBC?

A Flexible Intermediate Bulk Container (FIBC) is an industrial all-purpose container to carry a bulk of material between 500 kg to 2000 kg.

Woven PP (polypropylene) fabric is used to make these bags and this provides the bag with high strength, flexibility, and durability.

The industries in which Fibc is mostly used include:

- Food & agriculture

- Chemicals

- Pharmaceuticals

- Construction

- Mining

- Plastics & resins

- Fertilizers

Their design allows easy lifting with forklifts, cranes, or pallet mechanisms, making them ideal for storage and transport.

Why Are FIBCs Called “Flexible Intermediate Bulk Containers”?

Every word in its entirety is meaningful:

1. Flexible

The bag material is of tough woven fabric which can be bent without snapping.

2. Intermediate

It is not too large or too small like sacks that are used by industries.

3. Bulk

Intended to transport high loads (in many cases more than 1 ton).

4. Container

It holds and carries such materials as a container though in a light form.

The name is ideal in describing the product.

Common Names for FIBC Bags

FIBCs can also be referred to as:

- Bulk Bags

- Jumbo Bags

- Super Sacks

- Big Bags

- Tote Bags

- WPP (Woven Polypropylene) Bulk Bags

These names are based on the usage in the regions yet they allude to the same product.

How FIBC Bags Are Made

FIBCs are made up of woven polypropylene of high strength. The production process usually entails:

- Extrusion of PP granules

- Weaving the polypropylene fabric

- Cutting and printing

- Sewing (U-panel, circular, or 4-panel design)

- Adding loops, spouts, or liners

- Quality testing for SWL and safety factor

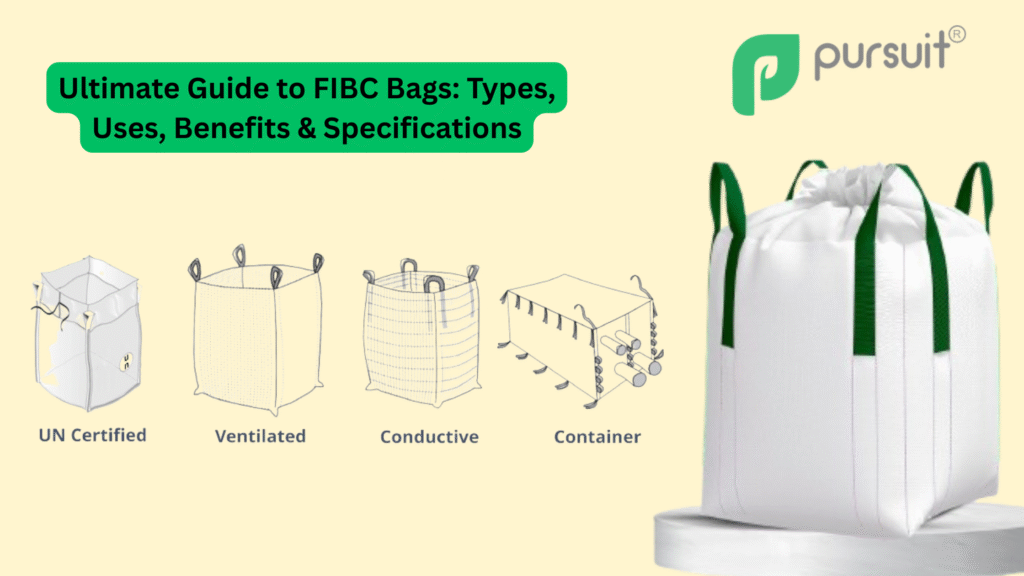

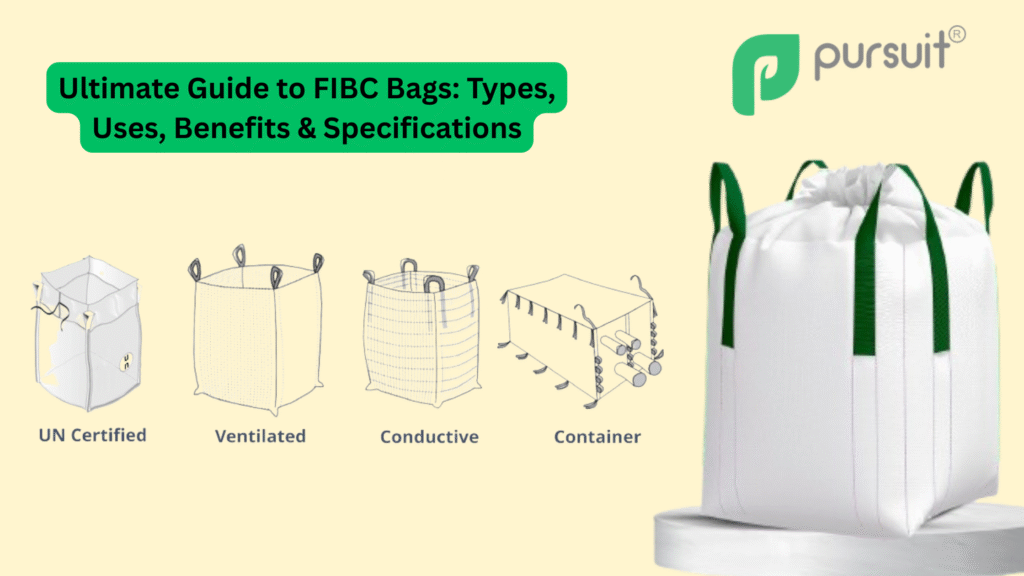

Types of FIBC Bags

The knowledge of the kinds assists in choosing the appropriate bag depending on the material, environment and the static safety.

1. Type A — Standard FIBC

- No static protection

- For non-flammable products

- Used in general industries

2. Type B — Surface Breakdown Voltage

- Grabs propagating brush discharges.

- Applied to dry, combustible powders.

3. Type C — Conductive Bags

- knitted with conductive yarn.

- Should have a footing at the time of filling and discharge.

4. Type D — Anti-Static Bags

- Safe discharge of statical electricity.

- No grounding required

- Best suited in flammable surroundings.

FIBC Bag Designs

U-Panel Bags

U shaped design made of 3 panels; very common.

Circular Bags

Mostly woven in a tube form; no side seams.

4-Panel Bags

Constructed using four separate panels; holds its own better.

Baffle Bags (Form-Stable Bags)

Interior baffles are square in shape and space maximizing.

FIBC Liners

There are materials that need extra protection. Liners are added for:

- Food-grade products

- Moisture-sensitive materials

- Fine powders

- Chemical safety

Types of liners include:

- Form-fit liners

- Lay-flat liners

- Aluminum liners

- Conductive liners

Key Features of FIBC Bags

- High Safe Working Load (SWL) — 500 kg to 2000 kg

- UV-stabilized

- Moisture protection

- Reusable and recyclable

- Easy filling and discharge spouts

- Forklift-friendly loops

Applications of FIBC Bags

The industries that utilize the use of the FIBC bags are:

1. Agriculture

Grains, seeds, fertilizers, feed.

2. Chemicals

Powders, resin, pigments.

3. Construction

Sand, cement, gravel.

4. Food Industry

Sugar, flour, spices, starch.

5. Pharmaceuticals

API, bulk powders.

6. Mining

Minerals, ores.

Advantages of FIBC Bags

- Cheap in comparison with hard-packaged containers.

- Less storage space needed

- Light in weight yet very powerful.

- Adjustable in terms of size and functionality.

- Lower shipment and transport expenses.

- Reusable and eco-friendly

How to Choose the Right FIBC Bag

When selecting an FIBC, consider:

- Product type (powder, granules, food, chemicals)

- Required lifting style

- Static protection (Type A to D)

- Need for liners

- SWL & safety factor

- Filling & discharge mechanisms

- Environmental exposure

FIBC Full Form vs. Related Terms

| Term | Meaning |

|---|---|

| FIBC | Flexible Intermediate Bulk Container |

| Jumbo Bag | Common industrial name for FIBC |

| Bulk Bag | Refers to large capacity FIBC |

| Super Sack | Mainly used in the US |

| Big Bag | Commonly used globally |

FAQs About FIBC Full Form

1. What is the full form of FIBC?

Ans: FIBC stands for Flexible Intermediate Bulk Container.

2. Are FIBC and jumbo bags the same?

Ans: Yes, both refer to the same industrial packaging bag.

3. What material is used to manufacture FIBCs?

Ans: Woven polypropylene (PP).

4. What is the capacity of an FIBC bag?

Ans: Typically 500 kg to 2000 kg.

5. Why are FIBCs so popular?

Ans: They are strong, lightweight, reusable, and cost-efficient.

Conclusion

One of the most effective, reliable, and cost effective solutions in bulk handling of materials in any industry is the Flexible Intermediate Bulk Containers (FIBCs).

They are critical to contemporary industrial packaging because of their strength, customisability and versatility.

Ultimate Guide to FIBC Bags: Types, Uses, Benefits & Specifications

Flexible Intermediate Bulk Containers also referred to as FIBB bags are an essential solution to bulk material management in industries across the globe.

Their strong structure, large capacity and flexibility make them the preferred choice when it comes to material transportation as well as storage.

FIBC bags in the agriculture, chemical, construction, or pharmaceutical industry are safe, economical, and convenient to use in industrial practice.

What Are FIBC Bags?

FIBC Bags (complete name: Flexible Intermediate Bulk Containers) are woven polypropylene bags, large and strong, which are used to store and transport large amounts of products: grains, chemicals, sand, fertilizers, cement, plastics and others.

They can be used to work with grains and fertilizers as well as chemicals and building materials.

Primary Uses:

- Agriculture: Storage and transportation of grains, seeds and manural.

- Chemicals: How to pack powders and granules safely.

- Construction: The aggregate, cement, and sand transportation.

- Pharmaceuticals: OSHA Medicinal powder and ingredient handling.

- Mining: Saving value of minerals and ores.

What are FIBC bags used for?

They are applied in the safe storage and transportation of high tonnes of dry bulk contents in different industries.

FIBC Bags vs Other Bag Types

How FIBC Bags Differ from IBC Containers

FIBC bags do not share much in common with Intermediate Bulk Containers (IBC) except in material and construction.

The IBCs are typically hard containers composed of either plastic or metal whereas the FIBC bags are lightweight, flexible and foldable.

What is the difference between IBC and FIBC?

FIBCs are flexible and space saving whereas IBCs are more rigid in offering protection and stack easily.

FIBC vs PP Bags

Smaller single-use bags consist of polypropylene (PP) bags mostly applied to 2550 kg materials.

FIBC bags can also carry 2,000 kg and above and can even be reused hence making them a more viable option.

What is the difference between PP bags and FIBC bags?

FIBC bags are bulk reusable and larger as compared to the normal PP bags, which are used in bulk industrial purposes.

FIBC Bags Full Form and Specifications

FIBC stands for Flexible Intermediate Bulk Container.

Specifications:

Sizes & Dimensions: Vary depending on application; typical volumes range from 500–2,000 kg

Weight Handling Capabilities: Safe Working Load (SWL) of 500–2,000 kg

Materials:

- Polypropylene (PP)

- UV-resistant coatings

- Anti-static additives

- Optional colorants

What is FIBC made of?

FIBC bags are mainly composed of the woven polypropylene, which is commonly coated or treated according to a chosen industrial need.

Types of FIBC Bags

By Electrostatic Classification

- Type A: Non-conductive, regular bulk bag.

- Type B: Conductive and has a little electrostatic resistance.

- Type C: Groundable conductive FIBC.

- Type D: Complete anti-static of flammable powders.

By Shape & Construction

- U-Panel FIBC: The easiest to construct, the cheapest.

- 4-Panel FIBC: stronger structure, even distribution of weight.

- Circular FIBC: Body is seamless and has high volume capacity.

- Baffle FIBC: Square in shape to make the most of the space.

- Other Constructions: Corner lift, cross corner lift, sleeve lift.

By Application / Industry

- Agriculture: Grains, seeds, fertilizers

- Animal Products: Supplements, bedding and Feeds.

- Food & Pharma: Pharma and food grade powders.

- Chemical & Hazardous Materials: Chemicals: safe storage.

- Construction & Mining: Cement, sand, minerals

FIBC Bag Styles & Tops/Bottoms

- Best Sellers: open top, duffle top, spout top, spout top with flap, conical spout top.

- Bottom Options: plain bottom, discharge spout, conical discharge spout, duffle bottom.

Such differences give the ability to customize it according to industry needs and material type.

FIBC Bag Manufacturing & Materials

Raw Materials:

- Polypropylene resins

- UV stabilizers for sunlight resistance

- Calcium carbonate

- Anti-static additives

- Colorants for product differentiation

Manufacturing Process:

- Extrusion of polypropylene into tapes

- Weaving of fabric

- Lamination or coating for additional protection

- Stitching and finishing of loops

- Quality tests to meet regulatory standards

Also Read : https://pursuitind.com/fibc-bags-manufacturer-in-india/

Choosing the Right FIBC Bag

Factors to Consider:

- Weight and material volume

- Electrostatic requirements

- Coating type (coated vs uncoated)

- Top and bottom style

Industry-Specific Recommendations:

- Agriculture: Baffle or U-panel

- Chemicals: Type D anti-static

- Construction: 4-panel or circular for heavy loads

Which type of bulk bag is right for you?

Choose based on material type, weight, and regulatory requirements.

Advantages of FIBC Bags

- Large storage capacity

- Lightweight and easy to handle

- UN certified for hazardous material transport

- Reusable and sustainable

- Customizable for prints, loops, and coatings

Common FAQs About FIBC Bags

1) What does FIBC stand for?

Ans: Flexible Intermediate Bulk Container.

2) What are FIBC bags used for?

Ans: Movement and storage of dry bulk goods.

3) What are the number of combinations of FIBC bags?

Ans: Different models according to the construction, shape, and also electrostatic classification.

4) Difference between FIBC and IBC bags?

Ans: FIBC is flexible; IBC is rigid

5) Distinction between PP bags and FIBC bags?

Ans: FIBC bags are larger in capacity, reusable and bulk.

Conclusion

FIBC bags constitute a fundamental answer to contemporary industrial storage and transportation. They are versatile, strong and adapting to a vast number of industries.

The appropriate choice of the type of the FIBC bag can guarantee safety, efficiency, and sustainability of the material handling.

In the case of companies that are in need of bulk packaging solutions of high quality, it is advisable to contact a reputable manufacturer of the FIBC bags so that you can get one that suits your exact needs.