Blog

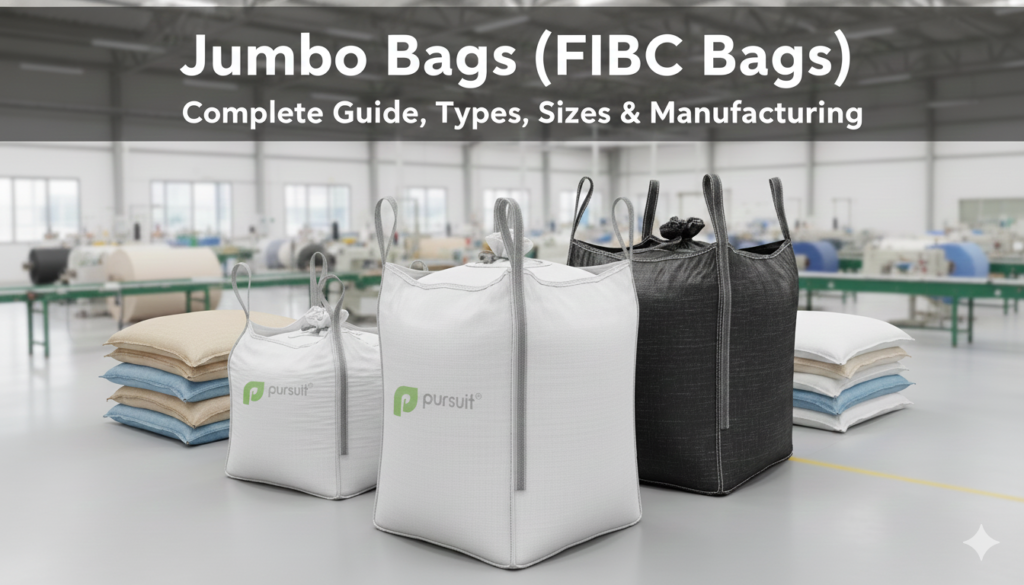

Jumbo Bags (FIBC Bags): Complete Guide, Types, Sizes & Manufacturing

Jumbo Bags commonly referred to as FIBC (Flexible Intermediate Bulk Containers) has emerged as the surest and cost effective method of transporting and storing bulk materials.

These are industrial grade bags which have a capacity of carrying heavy weights of between 500 kg and 2000 kg making them suitable in manufacturing, agriculture, chemicals, construction and export businesses.

In the modern supply chain systems, 1 ton jumbo bags and other high strength FIBG bags have taken the form of a global standard since they are durable, safe, and cost-effective.

This all inclusive guide explains all about Jumbo Bags, their types, uses, sizes, costs and the reason why businesses use them.

Introduction to Jumbo Bags (FIBC Bags)

A Jumbo Bag is a large, woven polypropylene (PP) bulk bag used for storing and transporting powder, granules, flakes, and other bulk materials.

These bags are strong, reusable, and designed for heavy-duty industrial applications.

They are also called:

- FIBC Bags

- Bulk Bags

- Big Bags

- Intermediate Bulk Containers

- 1 Ton Bags

Jumbo Bags are widely used because they:

- Reduce packaging cost

- Carry large volumes in a single bag

- Are lightweight yet extremely strong

- Safe lift/Transport Forklifts or cranes.

Industries use them in preference in fertilizers, grains, cement, minerals, chemicals and sand, aggregates, polymers among others.

For high-quality bulk packaging solutions, manufacturers like https://pursuitind.com/ supply premium-grade Jumbo Bags across multiple industries.

Types of Jumbo Bags

Standard FIBC Jumbo Bags

These are the most common bags used in industries for 500 kg to 2000 kg material carrying capacity. Types include:

- Circular Jumbo Bags

- U-Panel Jumbo Bags

- Four-Panel Bags

- Baffle Bags

These bags are widely supplied by companies such as Leading FIBC & Jumbo Bag Manufacturer for bulk packaging.

Specialty Jumbo Bags

Special packaging industries use these advanced variants:

- Conductive / Type C Bags – Prevent static electricity

- Antistatic / Type B Bags

- Food Grade Jumbo Bags – For sugar, grains & food products

- UN Certified Bags – For hazardous materials

- Ventilated FIBC Bags – For potatoes, onions & vegetables

Single & Two Loop Jumbo Bags

Used mostly in fertilizers, seeds, and cement industries. They are ideal for crane and hook lifting.

Plastic & Poly Jumbo Bags

These include:

- Jumbo Poly Bags

- Jumbo Plastic Bags

- Polyethylene-lined FIBC Bags

- Jumbo Polythene Bags

Jumbo Garbage Bags

Used for industrial waste, municipal waste, and large-scale disposal operations.

Jumbo Bean Bags & Other Variants

These include:

- Jumbo Bean Bags

- Jumbo Bean Bag with Beans

- Bean Bag Jumbo Size

These are consumer products but fall under the keyword category.

Jumbo Bag Sizes & Dimensions

Sizes vary based on volume, capacity, and application.

Most Common Sizes:

- 1 Ton Jumbo Bag – 90 x 90 x 110 cm

- 1 Ton (Large Volume) – 95 x 95 x 125 cm

- 500 kg Bag – 75 x 75 x 90 cm

- 2000 kg Bag – 105 x 105 x 135 cm

Typical range of dimensions:

- Length: 80–120 cm

- Width: 80–120 cm

- Height: 90–180 cm

Manufacturing Process of Jumbo Bags

FIBC bags are produced in several phases:

Raw Material Preparation

Polypropylene granules of good quality are woven.

Fabric Weaving

Circular weaving or flat weaving machines create woven PP fabric.

Cutting & Printing

Fabric is cut precisely, and custom branding is printed.

Stitching & Loop Attachment

Strength stitching is high so that it holds loads.

Liner Insertion

PE liners may be inserted for moisture-sensitive products.

Testing & Certifications

Global manufacturers like Pursuit follow:

- ISO standards

- Food-grade certifications

- UN hazardous material standards

Top Jumbo Bag Manufacturers in India

India is one of the world’s biggest exporters of FIBC bags. Leading manufacturers supply domestic and export markets.

Major Manufacturing Regions

- Gujarat

- Maharashtra

- Rajasthan

- Tamil Nadu

Industries Using Jumbo Bags

Jumbo Bags are used globally across:

Agriculture

- Seeds

- Grains

- Fertilizer

- Animal feed

Construction

- Cement

- Sand

- Concrete mix

- Aggregates

Chemicals & Minerals

- Powdered chemicals

- Minerals

- Pigments

- Polymers

Food & Pharma

Food-grade bags are used for hygienic packaging.

Waste Management

Large jumbo garbage bags help with bulk waste storage.

Bitumen Packaging

Companies like Pursuitind supply 1-ton and FIBC bags for bitumen and industrial chemicals.

Applications & Use Cases

Jumbo Bags are used alongside systems like:

- Jumbo Bag Filling Machines

- Jumbo Bag Packing Systems

- Jumbo Bag Unloading Systems

- Conveyor-based filling solutions

These machines enhance speed and safety in bulk operations.

Technical Specifications of Jumbo Bags

GSM Range

120–240 GSM depending on strength requirement.

SWL (Safe Working Load)

500 kg – 2000 kg.

Safety Factor (SF)

Standard: 5:1

Heavy-duty reusable: 6:1

Loop Types

- Corner loops

- Cross corner loops

- Sleeve lift loops

Bottom Designs

- Flat bottom

- Spout discharge

- Conical discharge

Jumbo Bag Branding & Companies

Pursuit Industries – A Trusted Manufacturer for High-Quality Jumbo Bags

When it comes to premium, export-quality Jumbo Bags, Pursuit Industries stands out as one of the most reliable manufacturers in India.

Pursuit Industries specializes in producing strong, durable, and customizable FIBC Jumbo Bags that meet the requirements of multiple industries including construction, agriculture, chemicals, minerals, polymers, bitumen, and food-grade applications.

Why Pursuit Industries Is Trusted for Jumbo Bags?

✔ High-Strength Material

Pursuit uses top-grade woven polypropylene (PP) fabric with excellent load-bearing capacity for 500 kg to 2000 kg materials.

✔ Customized FIBC Bag Designs

They offer multiple types of jumbo bags such as:

- U-panel bags

- Circular woven bags

- Baffle bags

- Food-grade bags

- UN certified bags

- Liner-integrated bags

✔ Advanced Manufacturing Excellence

The company follows strict quality standards including:

- ISO-certified processes

- Multi-level fabric inspection

- UV stabilization

- International export guidelines

✔ Trusted Across Industries

Industries rely on Pursuit for:

- Fertilizers

- Minerals & powders

- Grains & seeds

- Cement & sand

- Bitumen handling

- Chemical packaging

✔ Bulk & Export Capabilities

Pursuit Industries has strong production capacity, ensuring timely supply for both domestic and international markets.

✔ Reliable Customer Service

Their team provides complete support—from selecting the right bag type to custom sizing, printing, and logistics assistance.

Rishi FIBC Solutions Pvt. Ltd.

One of India’s leading FIBC manufacturers with a strong global export presence.

They specialize in food-grade bags, conductive bags, UN bags, and ventilated jumbo bags.

Known for strict hygiene standards and advanced manufacturing technology.

Singhal Industries Pvt. Ltd.

A major producer of PP woven packaging materials including Jumbo Bags, PP sacks, liners, and HDPE products.

They offer customized FIBC solutions for chemicals, agriculture, construction, and industrial bulk packaging.

Bulk Corp International

Recognized for export-quality FIBC bags across Europe, the Middle East, and the USA.

They manufacture a wide range of Jumbo Bags such as U-panel, circular, baffle bags, and pallet-based bulk bags, all meeting global quality standards.

Related Jumbo Bag Products

- PP Woven Bags (25–50 kg)

- HDPE Bags

- Multi-wall paper bags

- FIBC liners

- Sling bags

- Pallets

- Two-loop bulk bags

These complement Jumbo Bag packaging solutions.

How to Store, Handle & Transport Jumbo Bags

Forklift Handling

Use loops for safe lifting.

Palletization

Bags must be stored on pallets in dry areas.

Safety Guidelines

Avoid dragging or dropping bags.

UV Protection

UV-stabilized fabric increases outdoor storage life.

Jumbo Bags vs Other Packaging Solutions

| Packaging Type | Capacity | Cost | Safety | Reusability |

|---|---|---|---|---|

| Jumbo Bags | Very High | Low | High | Yes |

| Plastic Bags | Low | Medium | Low | No |

| Drums | Medium | High | High | Yes |

| Cartons | Low | Low | Medium | No |

Jumbo Bags offer the best cost-to-capacity ratio.

FAQs

Q1. What is a jumbo bag?

A big PP woven bag that was used to transport 500-2000 kg materials.

Q2. What is the size of a 1 ton jumbo bag?

Typically 90x90x110 cm, but customizable.

Q3. What is the price of a jumbo bag?

Individual prices of between 250-900 per type and strength.

Q4. Which is the most appropriate jumbo bag company in India?

Industrial buyers prefer reliable manufacturers like https://pursuitind.com/ for bulk and export supply.

Conclusion – Why Choose FIBC Jumbo Bags?

Jumbo Bags represent the best package in the bulk material packaging across industries, which is economical, secure, and long-lasting.

They have a high load capacity, can be custom made, and are strong woven constructions which make them suitable to be used in long distance transportation and bulk storage.

Manufacturers like https://pursuitind.com/ play a vital role in supplying high-strength, export-quality FIBC Jumbo Bags suitable for chemicals, agriculture, construction, food, and bitumen industries.

Whether you need 1 ton jumbo bags, food-grade FIBCs, UN certified bags, or custom bulk packaging, Jumbo Bags continue to be the most dependable solution in 2025 and beyond.

Leading FIBC Bags Manufacturer in India — High-Quality Bulk Packaging Solutions

A common and cost-effective option of bulk handling of material is the Flexible Intermediate Bulk Containers or FIBC Bags as they are commonly referred to.

Being one of the reputable manufacturers of the FIBC bags, we sell strong, robust, and customizable bulk bags that are intended to serve those industries that require safety, efficiency, and heavy load carrying capacity.

What Are FIBC Bags? (Flexible Intermediate Bulk Containers Explained)

FIBC bags refer to the large, woven polypropylene bags that are used in transporting bulk materials like grains, fertilizers, chemicals, construction materials, plastics and mineral products.

Their light weight and very strong nature has made them a necessity in all industries around the world since they are known as Jumbo Bags or Bulk Bags or Big Bags.

Common types include:

- U-Panel FIBC Bags

- 4-Panel Bags

- Circular Woven FIBCs

- Baffle Bags

- Conductive (Type C) & Anti-Static Bags (Type D)

- Food-Grade and Pharma-Grade Bags

FIBC bags information source: https://en.wikipedia.org/wiki/Flexible_intermediate_bulk_container

Why Choose a Reliable FIBC Bags Manufacturer?

By collaboration with a reliable manufacturer, it is guaranteed that:

- Certified quality and safety

- Accurate load capacity (SWL)

- Food-grade clean-room production compliance

- Durable PP woven fabric material

- Customization as per your industry needs

- Leak-proof and moisture-resistant stitching

An excellent manufacturer ensures the quality of packaging which is reliable and remains constant and ensures that your products are safe throughout transportation.

Our Expertise as a Trusted FIBC Bags Manufacturer

Our bulk packaging solutions are global, with a long and practical experience, high-end technology, and professional in-house workforce.

Here’s what sets us apart:

- Years of manufacturing experience (E)

- Highly trained technical workforce (E)

- ISO/BRC-certified facility (A)

- Strict quality testing at every stage (T)

- Supply to major Indian and global industries (T)

Our commitment to quality ensures that every FIBC bag meets international safety and performance standards.

Types of FIBC Bags We Manufacture

We offer a diverse range of FIBC products, including:

- Jumbo Bags

- Bulk Bags

- Big Bags

- Baffle Bags

- U-Panel Bags

- Container Liner Bags

- Food-Grade & Pharmaceutical Bags

- Conductive & Anti-Static FIBC Bags

- Builder Bags for Construction

Every bag is customized based on material type, loop style, SWL, size, and application.

FIBC Bags Manufacturing Process (Step-by-Step)

In order to provide powerful and safe FIBC bags, we have a developed production process:

- Extrusion – PP granules are melted into tapes.

- Weaving –Tapes are woven in a robust PP cloth.

- Coating – To make it more resistant to moisture and durability.

- Cutting & Printing – Bags cut to fit and printed according to design.

- Webbing & Loop Making – Handles manufactured with high strength webbing.

- Stitching – Heavy-duty stitching to safely carry load.

- Quality Testing – UV tests, drop testing, load testing and leak testing.

- Packaging/ Dispatch – Final inspection and bulk shipment.

Key Features of Our FIBC Bags

Our FIBC bags are engineered with performance and safety in mind. They come with:

- High-strength woven PP fabric

- UV-stabilized material

- Moisture protection

- Strong lifting loops

- Inner liners for leakage protection

- Customizable dimensions & printing

- Safe Working Load (SWL) from 500 kg to 2000 kg

- Optional dust-proof, baffle, and ventilated variants

Industries Using FIBC / Jumbo Bags

Our FIBC bags are widely used in:

- Agriculture & farming

- Chemical industries

- Construction & cement

- Fertilizers

- Polymer & plastic granules

- Mining & minerals

- Food & pharmaceutical manufacturing

These industries prefer FIBC bags because they reduce packaging cost while improving safety and storage efficiency.

Benefits of Using FIBC Bags

Choosing FIBC bags provides several advantages:

- Highly economical bulk packaging

- Reduced transportation cost

- Space-saving storage

- Easy filling, lifting, and discharging

- Custom load capacity

- Reusable and eco-friendly

- Suitable for export packaging

Why We Are One of the Leading FIBC Bags Manufacturers in India

Companies prefer our FIBC solutions because we offer:

- Modern automated production

- Cleanroom facility for food-grade bags

- In-house testing and quality control

- Competitive pricing

- Large-scale production capability

- Custom design support

- Fast delivery across India and overseas

Our dedication to quality and service has helped us become a trusted bulk bag supplier for industries worldwide.

Frequently Asked Questions (FAQ)

1. What is the full form of FIBC?

FIBC stands for Flexible Intermediate Bulk Container.

2. What are FIBC bags used for?

They are used to store and transport bulk materials such as grains, cement, powders, granules, fertilizers, chemicals, and minerals.

3. What is the difference between FIBC bags and Jumbo bags?

There is no difference. Jumbo Bag is another name for FIBC Bag.

4. What is the capacity of an FIBC bag?

FIBC bags typically hold 500 kg to 2000 kg, depending on the design.

5. What is so good with an Indian manufacturer of FIBC bags?

India is a manufacturing center of one of the largest FIFO in the world that produces high quality, low-cost products that have export capability in other countries around the world.